Predispersed Rubber Chemicals - PREMIX® Range

Types

- Accelerators – CBS 80%, DCBS 80%, DDTS/MPTD 80%, DETU 80%, DOTG 80%, DPG 80%, DPTT 80%, DPTU 80%, ETU 80%, HMDC 70%, HVA-2 70%, MBS 80%, MBTS 80%, MBT 80%, MTT 80%, OTBG 50%, PO 60%, TBBS 80%, TBzTD 80%, TDEC 80%, TETD 75%, TMTD 80%, TMTM 80%, TRIAZINE 70%, ZADP 50%, ZBEC 80%, ZOBP 50%, ZDBC 80%, ZDMC 80%, ZDEC 80%, ZEPC 80%, ZMBT 80%

- Sulphur And Sulphur Donors – S 80%, S INSOLUBLE 80%, S INSOLUBLE HS 65%, DTDM 80%, CLD 80%

- Retarders – PTC 50/80%, VEAXIL 80%, VE 80%

- Inorganic Metal Oxides – ACTIVE 80%, ZnO 80%, ZnO TR 60%, MgO 74%, PbO 90%, Pb3O4 90%, Sb2O3 90%, TiO2 80%

- Antioxidants – AO 445 75%, AO 1010 80%, AO 2246 80%, MBM 80%, NDBC 80%

- Other Products – GB VEASIL 172 50%, GB VEASIL 6498 50%, MASTER GRAPHITE/E 40%, VEASTAT 3 40%, VEALUB 50M 100%, HMT 80%, ACTI T6, ACTI 7, AZ 80%, AZ/K3 80%, PENTAERITRITE 80%, OBSH 50%, SITS 50%, SARET 633 75%, VEASLIP 50%

- Formulated Granular Blends – GB JO 4061 (Curing System For EPDM), GB AF (Flame Retardant)

- Formulated Dry Liquids – ANTIOXIDANT TSP, EDMA, HMMM DL, PO DL, SILANE SI 69 DL, SILANE 172 DL, TAC, TBTD, TDAE DL, TRIM (TMPTMA), VEALUB 23 DL, ZADP MX

- Organic Colour Pigments Masterbatch – VEACOLOUR® range

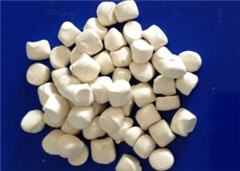

Gallery

Predispersed rubber chemicals and their uses

Rubber accelerators or accelerants are chemicals used to speed up the rubber manufacturing process (vulcanisation). This objective is to make untreated natural rubber latex suitable for manufacturing several rubber products.

Aside from the sulfur itself, sulfur bearing compounds that liberate sulfur at the vulcanization temperature can be used as vulcanizing agents. These are called sulfur donors. They are used to generate a network capable of resistance to degradation on exposure to heat. The main advantage of sulfur donors is that they reduce the normal blooming of sulfur in unvulcanized compounds.

Use of retarders in a variety of situations makes them a critical component of a rubber compounder’s toolbox of rubber technology. The most common use of retarders is to give a marginally processing stock some more scorch time. This might involve increasing the flow time in a mold or allowing a calendar to be run at a higher temperature for making a calendared sheet smooth.

Metal oxides are crystalline solids that contain a metal cation and an oxide anion. They typically react with water to form bases or with acids to form salts. The most important basic oxides are magnesium oxide (MgO), a good thermal conductor and electrical insulator that is used in firebrick and thermal insulation, and calcium oxide (CaO), also called quicklime or lime, used extensively in manufacturing and in water purification. The use of Magnesium Oxides in the rubber industry is very important to many halogenated and non-halogenated elastomers.

Granular blends consist of a mixture of several additives blended together in compact granules. The use of Granular Blends by one hand provides all the advantages already seen for PREMIX, by the other hand allows to add in the mixing the whole or the main part of additives in one step.

Dry liquids are required to avoid the problematic dosage of liquid additives. Advanced technologies allow homogeneous absorptions of any liquids, even the more viscous ones. The carrier consists in an inert silicate with high specific surface in order to minimize the wet effect and to increase the flowability. Dry liquids consists of unique blends of highly-absorbent amorphous silicas. These provide solutions to the problems of quickly incorporating high volumes of liquids within a compound without affecting the physical properties of the final vulcanisation.

Organic colour pigments masterbatches for polymers mass colouring are concentrates that transform thermoplastic and thermoset polymers from colourless and opaque materials to coloured. There are soluble colorant substances (dyes) and insoluble substances (pigments) that can be organic or inorganic, natural or synthetic. Combinations of these types of ingredients are contained in the modern masterbatches along with other non-colouring additives. It is through this complexity that it is possible to develop strength, depth, and resistance to colours.