Rubber Chemicals - RDC® Italy — Accelerators, Antioxidants, Anti-Scorching Agents and Peptizers

Types

- Accelerators - CBS, MBTS, MBT, DPG, DOTG, TMTM, TMTD, DPTT, DPTU, DTDM, TETD, ETU, NOBS, TBBS, ZDEC, ZDBC, ZDMC, ZMBT, ZBEC, DCBS, TDEC

- Antioxidants - 6PPD, TMQ, NDBC, MBI, ODPA, AO 445, SP OIL

- Anti-scorching Agents and Peptizers - PVI

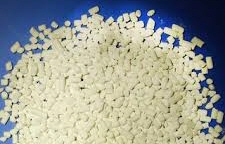

Gallery

Rubber chemicals and their uses

Rubber accelerators or accelerants are chemicals used to speed up the rubber manufacturing process (vulcanisation). This objective is to make untreated natural rubber latex suitable for manufacturing several rubber products.

The oxidation of latex and rubber compounds can have different effects, depending on the type of polymer involved. Problems include adverse colour changes, loss of flexibility, loss of tensile strength and reduced impact resistance, ageing, cracking and other surface deterioration. The use of our antioxidants protects against the effects of oxidation during production and storage.

An anti-scorch or retarder provides predictable scorch control in most sulfur vulcanization. It is suitable for natural rubber, styrene-butadiene rubber (SBR), Nitrile (NBR), Butyl, Neoprene, Ethylene Propylene Diene Monomer Rubber (EPDM), and Butadiene compounds.

During mastication, while performing compromise liquidation and cutting the molecular chains of the molecular cohesion with mechanical shearing force on the raw rubber, a peptizer is used to accelerate the cutting of the molecular chains. It also promotes plasticisation and reduces the mastication operation time by lowering the viscosity of the rubber.